Spoil pile and conveying equipment

Spoil pile and conveying engineering revolves around creating solutions for the conveying of bulk goods, such as coal, sand, ore or grains. Reliable and powerful bearings are an essential component here, since the conveying tends to take place under difficult weather conditions, and often in remote locations. Environmental influences, such as storms, earthquakes or extreme temperatures place high demands on bearings. This applies to the sealing system too. This must be considered during the design phase.

Our solutions in the field of spoil pile and conveying devices

Bucket excavators are amongst the largest excavators in the world. Their main field of application is extracting raw materials in large-scale and opencast mining. Bucket excavators are particularly well suited to lignite mining, given their considerable output levels of up to 240,000 tons per day.

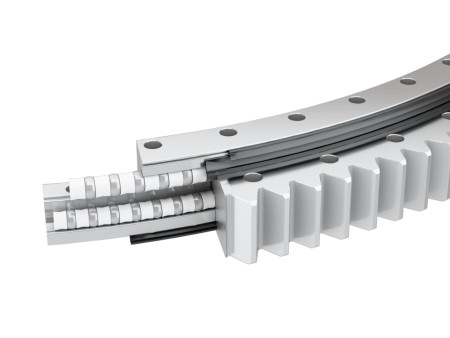

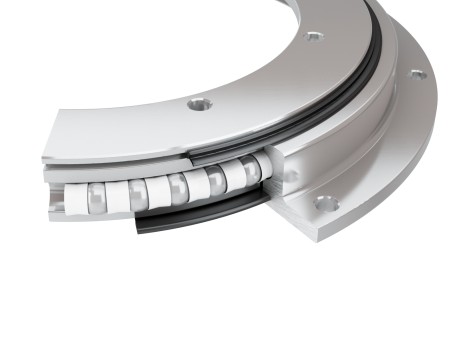

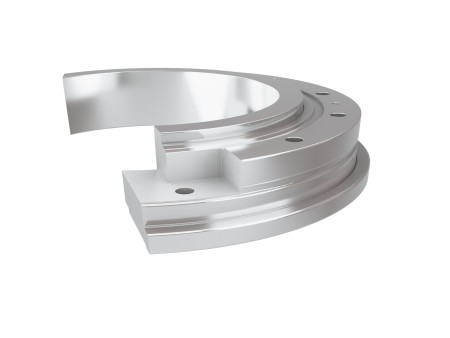

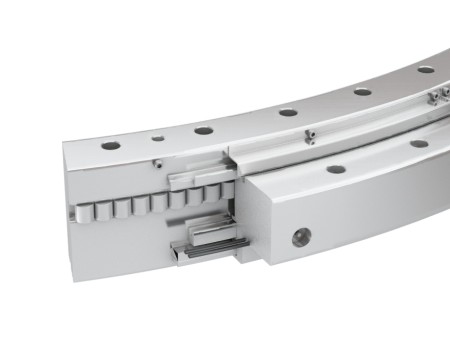

thyssenkrupp rothe erde bearings are used in several parts of these types of excavators to ensure that the several hundred metres high and several thousand tons of heavy machinery can be used effectively. This begins with the paddle wheel bearings, which must be especially protected against dirt, and extends to the portal bearing, which makes the swivelling of the upper structure on the chassis possible. Pivot bearings are used on the conveyor belts and spreaders, which are necessary for the handling of the spoil piles. Other applications include for bridge bucket wheel machines and drumming machines, which are used for the handling and mixing of bulk materials, and for the often 100-metre-long cantilever to which the bucket wheel is attached. Several slewing rings with various rotation axes are also used in a bucket excavator.

The accumulation of dust and dirt during extraction work is a big challenge for the technology. In order to prevent downtime due to defects, we bring our experience into collaborating with manufacturers.

Ship loaders and ship unloaders are important in ensuring the effective, material-saving and dust-free transportation of bulk goods on the shipping route. Coal, ores, phosphate, sulphur and fertilisers, but also food, such as grains, are fed onto continuously operational conveyor belts, and transported on a cantilever by means of the ship's open loading hatch. From there, the goods get to the ship's cargo space either in free fall, via a downpipe, or a slide.

For the ship to be optimally filled, it has to be moved under the cantilever. Elaborate manoeuvring can, however, be avoided if the cantilever’s unloading system is movable. This is where slewing bearings made by thyssenkrupp rothe erde come into play.

In a circular blending bed, materials can be both stored and stacked. It serves to store and homogenise key components, such as limestone, clay or coal, as well as mixes of limestone, marl and clay. A high stacking capacity of 2,500 tons and retrieval capacity of up to 1,500 tons per hour can be achieved by large circular blending beds. The advantage of circular blending beds is that there are no changes in stock piles. Thus, there are no shifts in the chemical composition of the retrieved materials. Compared to the longitudinal version, circular blending beds allow for larger stock levels, resulting from the base area covered. The continuous circular movements and the swivel movements of the distribution and retrieval devices often take place in a dirty environment. This places high demands on the bearings used. Slewing bearings made by thyssenkrupp rothe erde are ideal under such conditions, thanks to their durability and reliability.

Silos are used for the storing and mixing of bulk goods. This includes cement, powdered limestone, plastic granulates and also animal feed. Generally, a silo is filled from above and emptied from below. When material is removed, the uniform flow and optimal distribution of the different filling layers is, therefore, important. This is achieved by screw conveyors and other mechanical equipment. They blend goods which are to be filled at different times. Slewing bearings made by thyssenkrupp rothe erde are used to achieve the continuous rotations necessary. Since they are durable and resistant to bulk goods, they are perfectly suited to be used in this way.

The term mining excavator refers to the group of largest excavators with a bucket capacity of over 50 tons of material weight. These machines are mainly used in mines for the extraction of coal, ores, and other raw materials. The machine’s higher levels of mobility are its advantage over bucket excavators. This is achieved by means of the bearing, which ensures a connection between the upper structure and chassis of the excavator, enabling you to swivel around the whole work area.

Large excavators and mining excavators have an operating weight of around 50 to 200 tons. They are used in quarries and other, similar spoil pile areas. These excavators’ chassis generally have a chain drive. Harsh operating conditions and high levels of dust and dirt accumulation are also particularly challenging for the slewing rings between the chassis and body. Thanks to its many years of experience, thyssenkrupp rothe erde is always able find a suitable solution for the manufacturer, ensuring unnecessary operational downtime is avoided.

The reclaimer is a lifting device for heaped material, which needs to be transported from a stockpile for further processing. The diverse selection of models ensures all kinds of storage locations are catered to. These can visually resemble bucket excavators. Since swivel movements have to be carried out to remove a stockpile, our slewing bearings of varied dimensions are also put to use here.

The stacker mines bulk material stored at the end of the conveyor line in a targeted and continuous manner. The stacker consists of a chassis, a feeder of the materials to be stacked, and a rotatable upper structure with the ejection trailer. Spoil piles coming from the conveyor belt can be filled again at another location with a spreader. Slewing bearings made by thyssenkrupp rothe erde ensure the chassis and the upper structure are reliably connected.

/thyssenkrupp_logo_claim_d.svg)