Tunneling - Bearing solutions for tunnel boring machines

Rothe Erde has been supplying high-quality, robust and reliable bearing solutions for the tunneling industry for over 30 years. Since then, over 2,500 bearings have been manufactured for use in tunnel boring machines.

The leading equipment manufacturers in the field of tunneling technology rely on the expertise of Rothe Erde in a variety of bearing applications. Rothe Erde is the perfect partner for these critical applications. In addition to the know-how, customers appreciate the all-round package of reliable bearing solutions that we provide, which include: engineering, production and after-sales service.

The requirements for the components of a tunnel boring machine (TBM for short) are immense, as a failure during the construction of the tunnel can not only result in unimaginably high costs and delays resulting in missed deadlines, but in the worst case also result in damage to the image and loss of reputation of the TBM manufacturer. In cases where the a bearing needs to be removed from the machine during operation, this will certainly result in significant project delays.

As a leading bearing manufacturer, Rothe Erde works closely with the machine designer for each individual case to develop the optimal bearing solution for the cutter head as well as for the segment erector. Our scope of supply includes bearings for:

Full-face or partial-face cutting machines

Micromachines

Vertical boring machine

Customers of Rothe Erde particularly value the wealth of experience in design and manufacture of slewing bearings for tunneling of up to four meters and even much larger.

Would you like to contact us?

You are welcome to send us your request via our contact form.

Applications of Rothe Erde products in tunneling

Tunnel boring machines are used in transportation and infrastructure projects. These include subway construction, rail and road tunnels as well as tunnels for water supply and wastewater disposal.

A tunnel boring machine, which is a full-face cutting machine, allows the entire tunnel cross-section to be bored in a single operation. Depending on the geology, the machine simultaneously reinforces the tunnel wall by mounting so-called tubbings of reinforced concrete onto the wall with the help of an integrated segment erector.

The tunnel boring machine excavates a wide variety of rocks using a rotating cutter head. The main slewing bearing applications of the machine are cutter head bearings, also called main drive bearings.

The main drive bearing enables the rotation of the cutter head and the transmission of all resulting forces and moments.

In addition to the main drive bearing in a TBM, tunneling offers a wide variety of applications for our rothe erde® products:

Slewing bearings used in the segment erector

Bearings for microtunneling machines, roadheaders, etc.

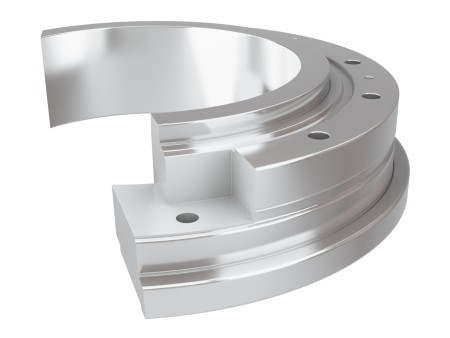

Rings (sealing rings, sealing support rings, cover rings, clamping rings, chambering rings, etc.)

Spherical bearings

psl® rolling bearing for the cutting wheels

Bearings for tubbing transport (transport carriage / transport crane)

Segmented bearings for special applications

Rothe Erde cooperates with tunnel boring machine manufacturers worldwide. Do you have any questions or would you like to send us a project inquiry? Please feel free to contact us.

We offer different bearing solutions for different products of tunneling

A multitude of aspects must be considered when building a tunnel, especially the ground conditions. This is what dictates which machine type is to be used. There are many different types available, such as mixed shield, gripper or EPB (Earth Pressure Balance) shields. These full-face cutting machines all have a cutter head which creates the hole through permanent rotational movements. This allows for the entire tunnel cross section to be removed in one step.

thyssenkrupp rothe erde supports the main bearing of the cutter head with specially manufactured roller bearing slewing rings. We have been working in this area since the early days of tunneling technology (see also lighthouse projects).

Roadheaders, which are mainly used in mining, do not have a cutter head in contrast to the full-face cutting machines. Instead, they carry out their function with one or several pivoted and flexible rotating arms. These machines also use rothe erde® roller bearings that have been designed for extreme loads.

Vertical boring machines are used to extract raw materials from great depths and to create shafts. There are different vertical boring machines to suit different usage scenarios. They work with roller slewing rings which are specially made to meet these demands.

Bearing solutions from Rothe Erde for your tunnel boring machine - This is why you should work with us

Reliability and the high quality of our products are our top priorities. In order to be able to guarantee the high quality, we manufacture our slewing bearings using methods and calculation procedures developed in the largest research and development center in the slewing bearing industry. The calculation methods (FEA) are constantly being developed further, so that we are always moving closer to the limits of what is physically possible.

We offer our customers a full range after-sales services. We are particularly well positioned in the bearing maintenance. Some bearings can be reused due to their high quality.

Our engineering, manufacturing and service teams have been cooperating with the leading manufacturers in the field of tunneling for years. Together with our customers, we design the bearing individually according to the environmental conditions, such as adjacent construction (drive train, tunnel diameter) and geology (loads).

Special projects such as three-row roller-bearing slewing rings with spherical bearings and sliding elements or segmented solutions are both particularly challenging and exciting for us. The trend towards larger tunnels as part of major infrastructure projects is increasing. Rothe Erde faces these challenges and looks forward to working with you to develop solutions for these new and exciting projects!

We are at work with you worldwide - Our lighthouse projects in tunnel construction

We have been working in the tunneling field since the earliest days of the industry. These projects started with the Eurotunnel between France and Great Britain and have continued on the the fourth Elbe tube in Hamburg and Tuen Mun-Chek, an undersea tunnel connecting parts of Hong Kong. In the last-mentioned project, the diameter of the tunnel bore is 17.60 meters. However, it is not only the size of the tunnel boring machine and the main bearing that need to be considered, but also the length of the tunnel. During the construction of the Gotthard tunnel in Switzerland, four machines were constant´ly in use for more than ten years to bore the tunnels, which were 57 kilometers long. Today, our bearing solutions are used worldwide.

/thyssenkrupp_logo_claim_d.svg)