Automotive engineering

As flexible modes of freight transport, lorries are at the centre of global logistics. The increasing demand for transport capacity is met by ever larger modes of transport. This introduces a unique set of challenges for manufacturers of semi-trailers and trailers since these transportation vehicles must be particularly agile on the narrow streets of our cities.

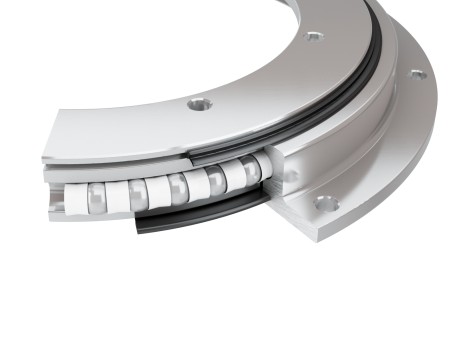

Slewing bearings by thyssenkrupp rothe erde are a key component for controllable axes. They also come in a turntable edition to be used with trailers. Drawing on their many years of experience, our engineers develop economical solutions to ensure freight transport remains safe and efficient.

The reliability, durability and ease of use of the slewing bearings made by thyssenkrupp rothe erde not only benefits the transporting of loads, but also of people. They can be found as reliable central swivel joint bearings and motor bogie bearings in many trams and articulated buses.

Our solutions in the field of automotive engineering

Unbeknownst to passengers, our bearings provide their services smoothly and reliably in trams. Today’s trains are markedly larger and more comfortable than older models, yet travel along as narrow a rail network as before. This poses great challenges for engineers, especially when it comes to curves.

thyssenkrupp rothe erde slewing rings help to solve this problem: Our bespoke central swivel bearings and motor bogies impart excellent driving features upon modern trains. Thanks to the durability and easy maintenance of our bearings, vehicles meet even the highest safety demands despite long service intervals.

The number of goods being transported on the roads is increasing more rapidly than the number of available transporters. In addition, the goods are becoming ever larger, longer and heavier. This means that semi-trailers must be upgraded too since to ensure efficient logistics, they must be able to move around securely in the existing transport network. The turning circle of the vehicle is the crucial factor here. In spite of large dimensions, it must be kept as small as possible.

Here too, slewing bearings made by thyssenkrupp rothe erde are used. Together with the manufacturer of the semi-trailer, our engineering team will develop a solution which enables large shipments to be carried out without interruptions and in an economical manner. Our bearings make it possible to precisely steer the additional axes of the semi-trailer. The result: good handling, even in narrow spaces. In this way, we make an active contribution to road transport security.

Trailers are vehicles with a loading area but without their own engine. In order to increase the loading capacity of a lorry, trailers are attached to the tractor unit. In most lorry trailers, the front axis is mounted onto a pivot plate. All loads are carried using this pivot plate when driving and braking. thyssenkrupp rothe erde turntables, which are based on experience gained from decade of service and subjected to continuous quality controls, assume the loads and make it possible for the front axis to swivel. Should you have any questions or require any information, our engineering team is always at your disposal.

In locations where building a network of trams is uneconomical or where this cannot logistically be carried out, articulated buses represent an alternative. Nonetheless, growing cities, narrower roads, badly parked vehicles, and a growing number of passengers present a new set of issues for bus manufacturers. To enable the vehicles to smoothly manoeuvre through the city’s traffic, high-quality joint slewing rings are needed.

Our engineers can draw on their experience in the field of slewing bearings when developing the articulated buses of tomorrow. With the highest quality and reliability standards, we provide manufacturers with the optimal conditions: Buses with joint slewing rings made by thyssenkrupp rothe erde remain a safe mode of transport, even under the strain of an emergency brake.

Skips, also called dumpers, are used on construction sites for the removal of excavation and construction materials. Everyday, hundreds of skips are used in large mining excavation fields. One single vehicle can transport a load of up to 400 tons. The skips bring valuable raw materials and excavation materials to the unloading sites, which are often far away, and where the material is either crushed or stored. A tiltable pit combined with a built-in slewing ring allows for precise unloading. Here too, solutions by thyssenkrupp rothe erde offer the optimal conditions for durable and smooth operation.

Turntable ladders are the vehicles most commonly used by the fire brigade. With these, people can be rescued from burning buildings and from great heights. For fire-fighting operations from above and at night, fire brigade turntables can also be used as mobile lighting masts. In order to be able to safely erect and turn the ladder, the precise, horizontal alignment of the vehicle is necessary. Uneven surfaces beneath can be manually evened out using extendible supports. Depending on the terrain, however, this procedure can be time-consuming and delay life-saving operations.

For this purpose, level-evening slewing rings made by thyssenkrupp rothe erde are the optimal solution: Special slewing rings even out the placement of the vehicle without losing any time and, thus, make safe work on the extended ladder possible.

Shipments of goods which exceed a given dimension or weight are classified as special shipments. For these, special vehicles are required, which allow for heavy loads and excessively long goods to be safely transported along narrow and bendy roads. Controllable wheel axes are needed for this.

thyssenkrupp rothe erde manufactures slewing rings with which vehicle manufacturers can separately control individual axes or take forced control of the axes.

Forklifts are becoming increasingly important in internal logistics: The loading and unloading of lorries, internal transport and the assembling of high-bay warehouses can all be rapidly carried out by these vehicles. Moving around the smallest of spaces and swivelling the lifted load are the most significant challenges to be solved by forklift manufacturers. A forklift swivel attachment, strengthened with durable slewing rings made by thyssenkrupp rothe erde offers manufacturers an economical and technically-sophisticated solution.

Slewing rings made by thyssenkrupp rothe erde are used in the field of communal utility vehicles, especially in the construction of refuse collection vehicles. In urban spaces, they are predominantly used for emptying comparatively small bins. In order to make the best use of the vehicles, the waste must be permanently compressed. For this reason, rear loaders with a main shaft bearing press system are popular: The waste is emptied into rotating chambers, then pulled over a screw conveyor in the direction of the tailgate which continuously presses it together. This process must function smoothly and be adjusted to suit low-maintenance, long operations. thyssenkrupp rothe erde's engineering team accurately design the slewing rings used to match the specified loads.

/thyssenkrupp_logo_claim_d.svg)