Military engineering

Military engineering ensures the security of our country and that of our allies. Military devices are used on land, water and in the air. That means, they must work reliably under extreme conditions and in all of the world’s climate zones. Our bearings are used both in heavy devices, such as armoured vehicles, and in sensitive optical devices. They are marked by their robustness, precision and reliability. Our bearing concepts are based not only on military norms and quality standards, but also on our decades-long experience and consequent research and development. Upon request, we are happy to carry out special measurements and tests in our R&D centre.

Our solutions in the military technology sector

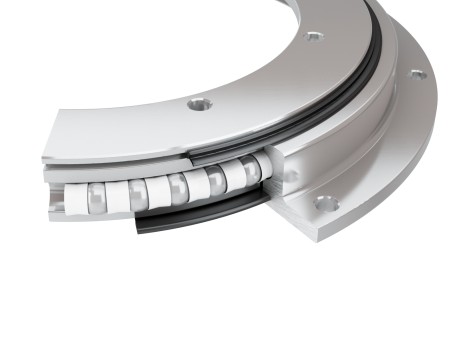

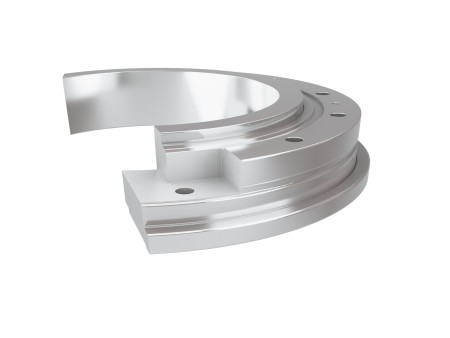

We design side swivel bearings for modern, stabilised towers - manned or unmanned - for battle and protection tankers, howitzers and air defence systems used on land and in water. Our bearings meet the requirements for lightweight construction and precision, and dispose of low and even rotational resistances. This remains true whether the journey be on terrain or at high sea. Moreover, part of our standard is for the bearings to be resistant to corrosion and to require minimal maintenance. Our height swivel bearings can be designed as fixed/fixed or fixed/loose bearings and have the same advantages as side swivel bearings.

Machine guns are used both in mountings (racks of weapons) and in remotely-controlled weapon stations. Since demands on the bearings vary greatly, a variety of models are used here. From simple turntables through to solutions which correspond to a stabilised weapon tower in their design. To reduce the number of interfaces and the installation cost, further attachments, for example, drive designs can be partially integrated.

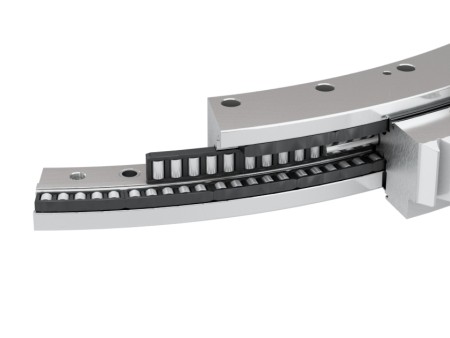

Radars are used in air surveillance and in air defence, to be able to detect and track targets up to 2,000 kilometres away. Our bearings are built to meet the precision, rigidity and low and even turning resistance requirements, while also performing at high speeds.

Although there is a large variety of optical devices, they all have one thing in common: Shocks and vibrations must not be transmitted to the optics, or only to a very limited extent. Thus, the bearings used here must be highly precise, rigid and dispose of even turning resistance. All this, in a strictly defined scope.

Recovery and engineer devices have cranes and excavators. The surfaces of the bearings used are generally hardened, which makes them suited to the special, military requirements. Particularly robust designs are used for particularly harsh assignments.

Naval artillery and armoured vehicles have loading machines. The ammunition can be found here in rotationally-symmetric magazines. The mobile handling machines require bearings without backlash with low and even turning resistances.

In a track-driven vehicle, for example, a tank, the roller is part of the track drive on which the vehicle is placed. Without rollers, it would not be possible to have a vehicle with a track drive. The intelligent use of steel allows for a better running performance in comparison to when rollers made of aluminium are used. Steel rollers are barely heavier, but a lot more robust, which reduces maintenance costs later down the line.

If gearing beyond the bearings supplied by us is needed, we will manufacture the required annular gears or annular gear segments for the engine. These components are also used to drive position transmitters where gearing must be particularly precise. Drive and measurement gearing can be integrated into the same annular gear or annular gear segment.

/thyssenkrupp_logo_claim_d.svg)