Machine tools and production technology

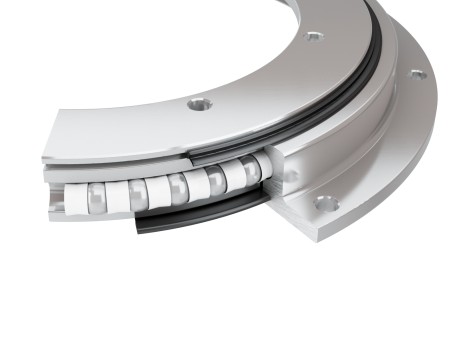

Machine tools can be divided into two categories: On the one hand, they comprise work machines and along with tools, devices, measuring and test equipment, they also count as operational materials on the other. Above all, lathes and milling machines need to be mentioned here. rothe erde® slewing bearings are used as bearings for the main processing axis, where the highest demands are placed on the concentricity and axial run-out.

Our solutions in the field of machine tools and manufacturing technology

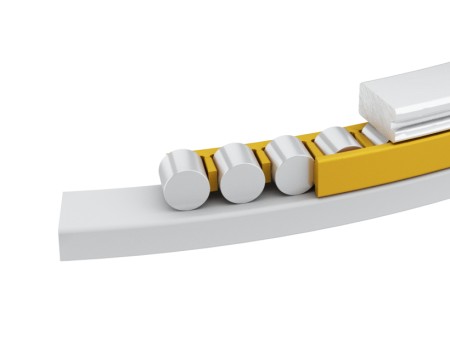

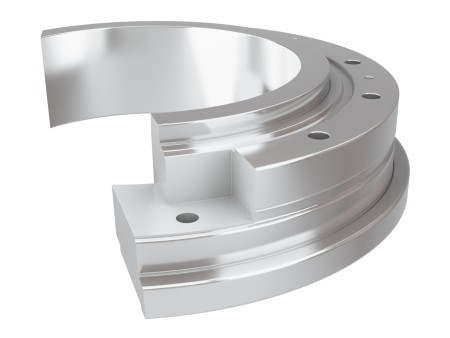

Face plates are clamping devices for lathes on which large, heavy, or irregularly shaped work pieces for processing are clamped in a vertical or horizontal position. For the storage of the face plates, slewing bearings with the highest levels of precision are needed. Only in this way can the high precision of the work pieces to be processed be ensured.

The tool changer is a mechanical setting at a machining centre. With this, the tools or process-relevant aids are automatically loaded or removed from the machining spindle. The actual changing process is carried out with single or double grippers, or directly from the magazine to the spindle (in the so-called “pick-up changer”).

Robots are playing an increasingly important role in industrial and production processes. The intelligent automation technology can be profitably used in almost all industrial processes. Robots combine maximum productivity and optimal manufacturing times. Made-to-order robot technology can give producing companies a decisive competitive advantage.

thyssenkrupp rothe erde has already been supplying rings and slewing bearings for robot technology for years. Only the highest quality standards are applied to our products so that they meet customers’ demands for productivity and durability.

Turntables are used in both machining in machine tools and in automation. Depending on their design, turntables can also be referred to as rotary tables, rotary indexing tables or dividing attachments. Depending on their use, they can also differ in terms of their shape or their precision and rigidity. In machining, the precision and rigidity demands placed on cutting processing are higher than in the non-cutting area. In contrast, in automation, the shortest switching times are required.

/thyssenkrupp_logo_claim_d.svg)