Maritime applications

The romantic idea of working on the high seas is deceptive. Stormy weather, burning heat and icy cold weather represent significant challenges both for people and materials. Under these conditions, offshore systems and their components must always work reliably.

The slewing bearings made by thyssenkrupp rothe erde boast the best of reputations in the offshore industry. They have been used in cranes, rudder post bearings, propeller shafts, and other maritime applications for decades already.

Our solutions for maritime applications

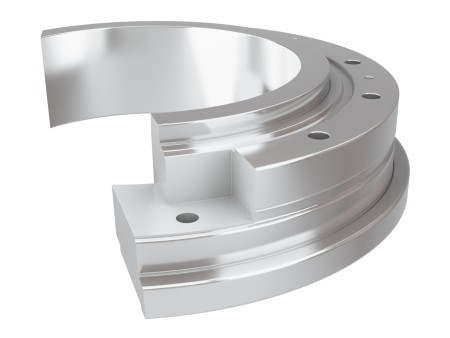

Propeller shafts are used in ships’ shafting to control the transfer of movements and thrusts between the engine and the propeller, as well as between the propeller and the body of the ship. Two different bearing models are used to support the propeller shaft: Radial and axial bearings The radial bearing functions as the main bearing, the axial bearings support by absorbing shocks and swinging movements. thyssenkrupp rothe erde offers reliable editions of both types of bearings, which enable propeller shafts to perform their best. This is how the power from the engine gets to the propeller and, finally, “into the water”.

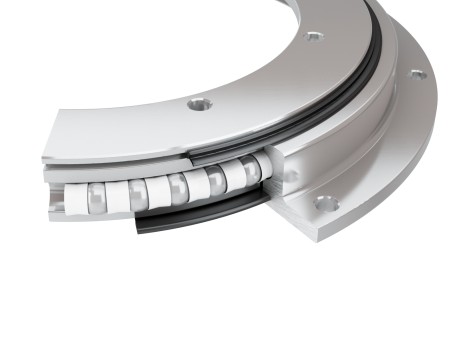

The rudder post is a part of the steering gear. It is responsible for ships changing direction and transfers the steering movement from the tiller to the rudder blade. Every rudder post has two to three bearing positions on the main rudder. Since the forces only work radially here, besides ball bearings, cylindrical or spherical roller bearings are also suited. For this field of application, our bearings are developed and manufactured based on customers’ wishes, right down to the smallest detail.

As part of anchor winches, bearings made by thyssenkrupp rothe erde help to haul heavy ship anchors everyday. This presents a specific set of challenges: Anchor winches are not in continuous operation. Thus, there are many periods of rest, during which the built-in bearings are at a prolonged standstill. Moreover, when selecting the appropriate type of bearing and bearing design, it is important to bear in mind that even during operation, only a low number of rotations occur but of heavy loads.

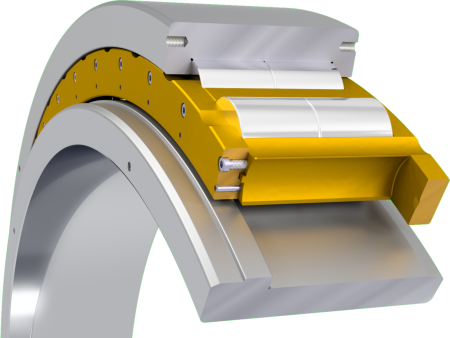

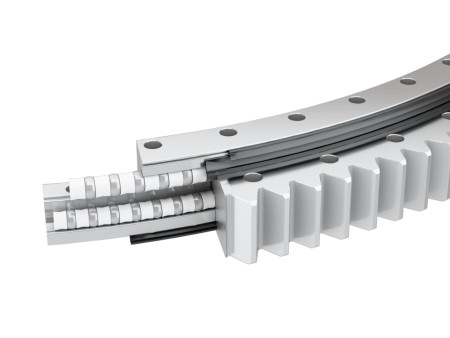

Rudder propellers are ship propulsions in which the propeller can be pivoted horizontally in any direction. The advantage of this over conventional motors with fixed propellers and rudders lies in its much improved manoeuvrability. Rudder propellers are typically used in cruise ships, ferries, icebreakers or dynamically-positioned drill ships. Slewing bearings with particularly precise gearing and long durability are used to make the swivelling of rudder propellers possible. Depending on the requirement, they are also equipped with multi-row sealing systems to prevent the entering of sea water.

Offshore gangways are used in both oil and gas extraction and in the offshore wind energy industry. They serve to transport goods and people between ships and offshore facilities. The extreme conditions on the high seas place the highest of demands on the design and quality of our slewing bearings.

Anchor handling tug supply vessels are assistance vessels for oil rigs, pipelayers and for any other offshore structure without an engine. The pulling and moving of the anchor places high demands on the winches. For this, thyssenkrupp rothe erde offers annular rings or slewing bearings with horizontal rotational axes, which can be adjusted to fit with the relevant customer design.

Offshore cranes are especially designed for use on the high seas, and are best equipped for this particular challenge. They fulfil an important function in the field of oil and gas extraction, as well as in the installation and maintenance of offshore wind turbines (WEAs).

For this field of application, the bearings made by thyssenkrupp rothe erde are developed, down to the finest detail, in conjunction with the customer, and designed and finished in accordance with the applicable classification society. This ensures maximum safety and an economically optimal design. If required, we can also monitor these bearings once installed, using especially developed test systems.

Deck cranes have replaced traditional derricks on freight ships as the on-board loading gear. Today, this term comprises all ship cranes and lever mechanisms which load or unload goods. They are an important player in fast cargo handling, especially when no cranes with sufficient lifting capacity (SWL) are available in the destination port. The lifting capacity of modern ship deck cranes lies at between 5 and 1000 tons, depending on the profile of requirements.

Here, robust slewing bearings are in demand: They guarantee the swivel capacity of a ship deck crane under adverse maritime conditions. Different solutions are required depending on the application. Sometimes, heavy loads are moved at irregular intervals, whilst other crane systems must achieve high periods of operation when handling lighter and mid-sized loads.

For each application, thyssenkrupp rothe erde offers an extensive selection of well-established solutions. For this field of application, the bearings are developed, down to the finest detail, in conjunction with the customer, and designed and finished in accordance with the applicable classification rules.

/thyssenkrupp_logo_claim_d.svg)