rothe erde® rings - Quality that convinces

Thanks to our 160 years of experience in the steel forming and mechanical machining industries, rothe erde® rings shine through high performance. With the know-how from open die and impression die forging, we were able to perfectly apply the technology needed for seamless rolled rings (radial-axial-rolling mill technology) from the very beginning and to continuously develop this. This manufacturing process offers crucial economic and technical advantages, in contrast to other processes, such as using thick plates in manufacturing. In particular, the typical tangential grain orientation for rolled rings ensures isotropic mechanical properties around the entire circumference of the ring.

Our high demands on the material quality are met by the expertise of our employees in ingot and continuous casting, electroslag remelting and forging. Only if we can meet the broad spectrum of our customers demands will we meet our own requirements.

Rothe Erde manufactures rings at the following locations:

Germany

USA

China

In this way, we can map different local requirements from a single source. To ensure that the products arrive quickly and safely at their destination, we also support our customers with a variety of logistical solutions.

Besides their use in slewing bearings, rothe erde® rings’ applications range from industrial machinery, automotive engineering, aerospace to wind turbines and tunnel boring machines. Forged rings are used in large gears, large valves, production systems, gear rings and in pipeline construction. This diversity is primarily possible by the fact our rings are machined in-house. The experience gained over many years enables rothe erde to respond to today’s and tomorrow’s market challenges.

Do you want to contact us?

Then give us a call, write an email or fill out our contact form.

Our promise to you

We can meet customer requests and agreed delivery dates. How is that possible?

We take flexible measures as early as the consultation phase to help optimize the ring dimensions. In addition, the subsequent planning of incoming orders and control of production are highly flexible.

In order to guarantee this flexibility and short response times, we keep the most common materials in stock in various dimensions. The materials in stock are:

ingots and continuous cast grades

preformed and ESR materials

non-ferrous metals

standard aluminum alloys

The procurement of materials that are not permanently in stock is ensured by our worldwide connections.

We meet your individual requirements: we can choose between different production systems for different ring types and sizes. We decide on the most technically and economically optimal solution.

Our preheating furnaces have high-precision control and regulation devices that ensure material processing in the material-specific temperature range.

The processes are optimized during production to use the material as sparingly as possible to ensure the best possible material utilization and thus reduce costs to the lowest possible level.

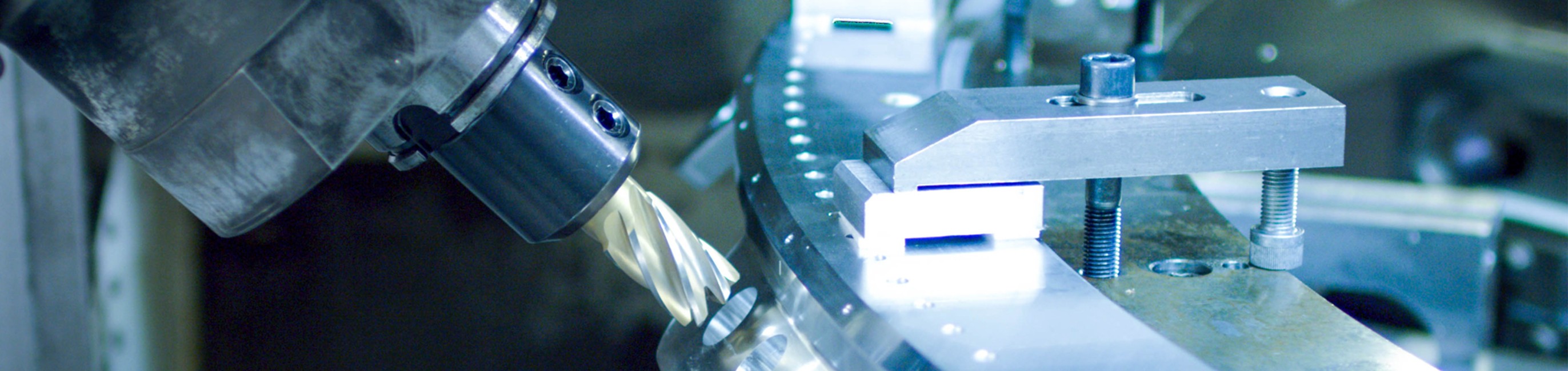

With our state-of-the-art ring rolling mills and our modern ring rolling technology, we can offer our customers all types of processing in addition to raw-rolled rings.

Our portfolio offers:

Internal gear cutting with straight teeth

External gear cutting with straight or angled teeth

Inductive flank or root hardening (depending on the usage)

Nitriding

Our offer can always be individually tailored to customer requirements.

rothe erde® rings are versatile. Some application examples are:

Rings and supporting rings for slewing bearings

Gear rings

Slewing bearings

Wind power plants

Offshore technology

Turbines

Generators

Transformers

Hydraulic motors

Large valves

Pipelines

Textile machinery

Tanks / pressure vessels

Aerospace and spaceflight

Bulk-feed presses

Steel mills

From planning to shipping - we make sure that errors are avoided and sources of error are consistently eliminated in all functional areas.

Our products are produced under the highest

quality

enviromental

economical and

working

standards. For this purpose, quality, safety and environmental goals are defined, which ensure that the available resources are appropriately assessed, measured and used. In addition, the effectiveness of all areas is increased and improved through regular reviews.

Our integrated management system is certified by the following standards:

Quality according to DIN EN ISO 9001 and according to DIN EN 9100

Environmental protection according to DIN EN ISO 14001

Energy management according to DIN EN ISO 50001

Occupational safety according to DIN EN ISO 45001

Sustainability, environmental protection, health and occupational safety are core elements in our corporate strategy. With our innovative product solutions, we want to make a positive contribution to the global development.

Our goal is to promote sustainable development through people-oriented corporate management and process control. We want to create a safe, clean and, above all, a healthy working environment for our employees and partners. Various preventive measures and risk controls are designed to prevent accidents at work. Our policies at thyssenkrupp rothe erde are based on the respective laws and regulations of the country.

Material-specific heat treatment and processing of our rothe erde® rings

Material-specific heat treatment and processing of our rothe erde® rings

Different material properties are required depending on the intended use. In addition to our decades of experience and in-depth knowledge, our state-of-the-art technical equipment and processes are essential to carry out material-specific heat treatment processes. In doing so, we strictly adhere to the specific time-temperature specifications of the special materials. In this way, we achieve optimal processing and application properties and can meet the most diverse requirements of our customers.

The precise ring dimensions also play an important role in the intended use. The ring dimension is supported by linked CAD and CNC programs. Even when sawing the ingot, the specified weights are precisely adhered to the modern high-performance saws with integrated weighing devices, so that we can achieve very tight manufacturing tolerances.

Did you know that our existing systems even meet the high requirements for the aerospace application area? Our products are of high quality, resilient and durable.

/thyssenkrupp_logo_claim_d.svg)